With modern facilities and a strict quality assurance system together with the latest technical know-how and many years of experience, Bregton looks forward to supplying its customers with top quality products.Bregton specializes in manufacturing high quality spare parts and components for Electrical Submersible Pumps and other equipment . In a very short time we can produce any part of ESP according to customer’s technical specifications or drawings.

|

|

Our high-efficiency electrical submersible pumps’ components ( impellers and diffusers ) features: > Flow rate : 95 bpd ~ 9500 bpd > Oil Well Casing internal diametre : from 4 inches to 8,1 inches > ESP diametre: from 3.38 inches to 7.6 inches |

|

|

|

|

Wide vane openings to heighten pump efficiency and extend system run-life Rectilinear vortex blades, which ensure a reduction in the axial force on the impeller, a high degree of wear resistance and reliability under conditions in which liquids with an increased content of mechanical contaminants are pumped. The higher efficiency is achieved by computerized selecting optimum values of inlet and outlet angles Corrosion and erosion-resistant coatings to protect high-efficiency stages Best-of-class inventory management Proprietary pump, impeller and diffuser coating designs to increase runtime in harsh environments |

|

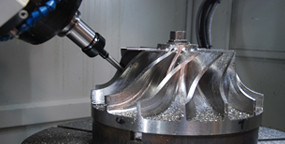

Bregton’s original method of calculation allows to create impellers and diffusers with requested parameters in a strict accordance with curves and data, presented by our client. In addition, Bregton invented and developed such cutting-edge processes and technologies : > 3D scanning and printing of molds > Low temperature testing (-70°C) > Nano-composite protective coating > Auto-balancing to reduce vibration Vibration plays a significant role in reducing pump life. Bregton uses various methods for a weakening vibrations’ influence, such as automatic balancing of impellers and diffusers and protector-head bearing, which is affected by vibration from the pump intake and abrasives in the produced fluid, uses an abrasion-resistant zirconium bearing. |

|

|

Control of Bearing Loads It is well known that lightly loaded bearings have longer lives. To achieve this, Bregton impellers and diffusers include design features that neutralize these loads. Radial Force Balance by Symmetrical Diffuser Geometry Properly proportioned diffuser vanes eliminate radial loads on the bearings thus assuring long bearing life. The mechanical balance is assured by symmetry and exacting dynamic balancing at the factory Radial Force Balance By Eliminating Hydraulic Instability Flow separation from the diffuser vanes can occur at low flow rates resulting in hydraulic instability (called “rotating stall”) with fluctuating radial loads on the bearings. Bregton eliminates these forces by careful matching of the diffuser and impeller. |

|

|

Axial Force Balance The axial force balance Bregton impellers and diffusers are carefully balanced by automatic dynamic balancing - a reliable and simple method of a significant reducing vibration and nullifying all axial (thrust) loads over the entire operating range of the pump. Bregton diffusers and impellers high fluid efficiency ( > 50% ) is achieved by optimizing the design parameters , such as : > Optimized vane angle > Appropriate diffuser/impeller inlet area > Ideal diffuser area ratio > Excellent surface finishing To achieve these goals Bregton utilizes a special up-to-date computer software. |

|

Bregton always pays great attention to creating customer-friendly products and technologies : > Simple and robust design make reliable work > Low weight and compact size strengthen durability > Easy assembling and dissembling reduce maintenance cost Because of the simplicity of the construction and a minimum number of parts, disassembly and reassembly can be done in a short time. The features include a stepless pump shaft, colleted impeller free of keys and bolts, and monolithic diffuser (casting assembly consisting of sleeve bearing and the casing). Bregton products’ cutting-edge materials, state-of-the-arts design and advanced industrial technologies helping oil companies optimize production, while protect their investments in oil lifting process. |

Bregton products have:

> Greater reliability

> High performance

> Enhanced endurance

Bregton impellers and diffusers are working stable even in most harsh environment.

Rather than evolving through a series of small design improvements, Bregton components were developed as a modular system engineered to enhance reliability and increase service efficiency and performance of down-hole ESP systems.

Bregton impellers and diffusers have been engineered for greater integrity. Bregton impellers use special “radial blades” to prevent components from trapping air bubbles while making up connections in the field, at the same time significantly increasing working characteristics.

Bregton design also removes certain critical installation operations from the wellsite. These improvements in service quality also helped to simplify the installation process of the Bregton unit, resulting in a significant reduction in rig time.

Thus, Bregton technology reduces exposure to potential environmental problems and human errors. Our ESP system’s components have demonstrated a significant reduction in operational and equipment problems, making Bregton products really customer-friendly equipment.